Are tyres replacing tailpipe as the policy priority?

Tyres are rapidly emerging as a new source of environmental concern and this will affect the car industry.

In a recently aired BBC radio documentary, it was claimed that the world will discard 3 billion tyres in 2019, enough to fill a large football stadium 130 times1. Beyond this broad issue of resource use and material waste, tyres also sit uniquely at the intersection of air quality and microplastics.

This newsletter sketches the problem in its current form and considers certain automotive developments in its light.

As a car drives by, you cannot see its tyres wearing and therefore ‘tyre wear’ in this sense remains imperceptible except in deliberately extreme use such as branches of motor sport such as drag racing and drifting.

Yet over a lifetime of between 20-50,000kms, a tyre will shed approximately 10-30% of its tread rubber into the environment, at least 1-2kgs2. The wear factor (defined as the total amount of material lost per kilometre) varies enormously depending on tyre characteristics such as size – radius/width/depth – tread depth, construction, pressure and temperature. In one recent Emissions Analytics’ test, conducted under real-world rather than lab conditions, the four tyres on a standard hatchback lost 1.8kg over just 200 miles of fast road speeds, far in excess of what had been anticipated by the testers.

A tyre abraids owing to the friction between its contact patch and the road surface. It ‘emits’ particles across a broad size spectrum, from coarse to fine to ultrafine to nanoscale. It may also emit other forms of aromatics such as benzopyrene and benzofluorene, the result of the incomplete combustion of organic matter resulting in evaporation of the volatile content of the tyres, which the EU has regulated to a degree3.

Coarse particles typically fall rapidly to the ground. At the fine level and smaller, they are airborne for a certain duration, either being blown away from the carriageway before settling on the ground, or falling to the carriageway where re-suspension may take place as other vehicles pass.

Particle dispersion and deposition eventually occurs, but that is not the end of the story. The particles typically pass into the watershed through street drainage and are estimated to be a primary source of as much as 28% of microplastics found in the marine environment4.

The recent re-characterisation of tyre wear emissions as ‘microplastic pollution’ corrects the broadly misleading public idea, out of date a hundred years and counting, that tyres are composed principally of natural rubber. Instead, tyres are a close derivative of crude oil and their wholesale pricing typically tracks it.

A typical car tyre comprises 45% oil-derived synthetic rubber (polymer), 40% oil-derived carbon-black (filler, 40%), and 15% various additives to aid production processes, some of which typically contain heavy metals and some of which are also oil-derived.

Some tyres contain natural rubber, but to all intents and purposes we live in the age of the plastic tyre.

For not unrelated reasons, we also live in the age of the disposable tyre. From being an expensive product derived in large part from natural rubber, tyres have fallen in cost as globalisation has catapulted numerous new entrant tyre-makers into what is today a $240bn a year industry.

If we now turn to the automotive world, tyres are more important than ever to vehicle attractiveness and performance, but for many different reasons:

An emphasis on vehicle and tyre performance is often at the price of tyre longevity, particularly where higher diameter wheel rim sizes are combined with wide tyres, whether to convey power or sportiness

Tyres have become more disposable as their price has fallen in real terms, replacing an older tradition of re-treading carcasses for extended life

New entrant tyre-makers in Asia, South Asia and Eastern Europe have led to the advent of the ‘budget tyre’

Electric vehicles offer instant torque and higher kerb weights, implying higher tyre wear rates, even while regenerative braking is expected to reduce brake wear emissions

Electrification leads to a completely new appraisal of the tyre in respect of durability and noise

In-cabin tyre noise becomes a high-concern consumer issue as drivetrain noise is reduced or eliminated.

From a regulatory viewpoint, tyres in Europe are labelled according to three criteria, (the so-called ‘performance triangle’): rolling resistance, wet grip and noise – but that may change as tyre environmental impact rises up the political agenda.

From our perspective, Emissions Analytics has been conducting in-depth real-world tests on tyres. Two immediate insights can be shared:

Budget tyres wear rapidly and have high emissions

New instrumentation capable of measuring emissions down to the nanoscale shows that at the ultrafine level and smaller, the particle mass becomes far less instructive than the particle number, which is much more significant, and yet current regulations only measure mass

The size distribution has potential implications for the epidemiology (health) concern around very fine particulate matter and how it may affect human health.

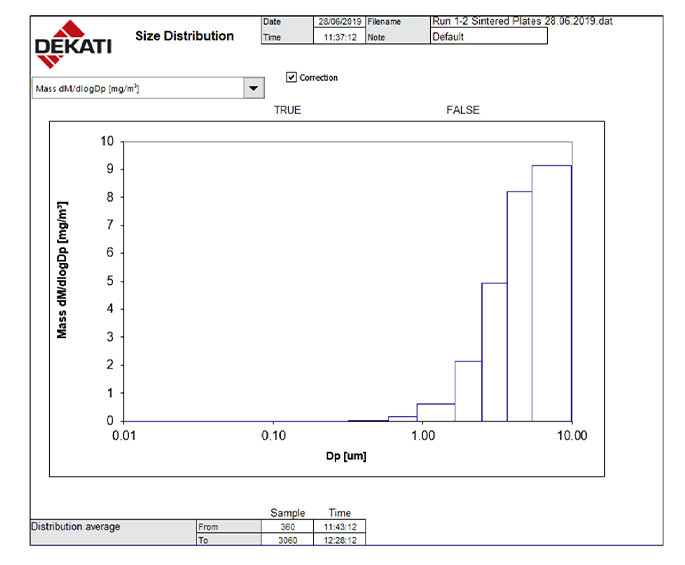

In one recent test, Emissions Analytics used a Dekati ELPI+ (Dekati® ELPI®+ Unit standard with 14 size fractions from 6nm up to 10um for PN/PM concentration at 1Hz/10Hz sampling rate) to measure both particle mass and number. The first chart below shows the resulting mass distribution.

We regard this as a valuable piece of data even though it only corroborates what is broadly known, that a comparatively small number of coarser particles (up to and including the 10 micrometre size shown in the far right column, familiar as PM10) account for most of the recorded mass.

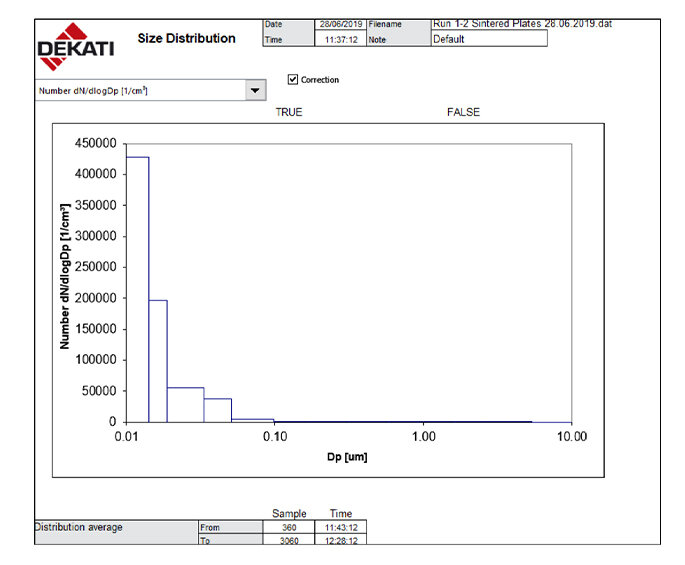

Then consider however the contrast when particle number is accounted for rather than mass: you get a mirror of the first graph, with a tiny amount of mass expressed as a very high number of nanoscale particles right down to the 10-nanometre level expressed in the first column (0.01 micro-metre).

This is a potentially valuable insight because until now this high particle number count has typically either not been measurable or not been measured, owing to a regulatory preoccupation with mass and a lack of suitably sensitive real-time measurement instrumentation.

The ability to count particles down to 10 nanometres relies on the quality of the impactor chosen for this test, which is considered to be the best currently available on a commercial basis.

Regarding public health, there is a tentative emerging consensus among epidemiologists and other medical researchers that ultra-fine particles are potentially more injurious to human health than coarse particles, owing to their ability to translocate to the bloodstream through the lungs5.

Particles will need to continue to be measured both for their mass and their number. In respect of mass they are emitted in a large size range by tyres. In respect of number they emitted in high volumes.

We highlight the UK government’s recent report Non-Exhaust Emissions from Road Traffic, authored by the UK Government’s Air Quality Expert Group (AQEG). It recommends “as an immediate priority that non-exhaust emissions (NEEs) are recognised as a source of ambient concentrations of airborne PM, even for vehicles with zero exhaust emissions of particles.”

Quite apart from the broader point here that so-called ‘zero emission vehicles’ are in fact significant sources of non-exhaust emissions, the quantity of such emissions is set to rise.

The same UK government report notes that non-exhaust emissions are believed to constitute today the majority source of primary particulate matter from road transport, 60% of PM2.5 and 73% of PM10. While regenerative braking is expected to reduce brake wear emissions, the increased weight and torque characteristics of alternative drivetrains such as EVs will likely be associated with increased tyre wear.

In the same report it is suggested that a 10kg increase in vehicle mass accounts for a 0.8-1.8% increase in nanoparticle emissions from tyres. This is particularly relevant as a whole generation of new EVs is hitting the roads with considerably larger and heavier battery packs than in the past.

For small to medium cars, where modest range is acceptable for city use or where the glider (bare chassis) has been deliberately lightweighted to offset batteries (as per the BMW i3), the weight gain may be marginal. Indeed, a switch to narrow tyres may neutralise or even reduce tyre wear.

But a Tesla Model S or Model X, Mercedes EQC, Audi e-tron or Jaguar i-Pace, EVs with larger ranges and battery packs in the range of 60-100 kWh, weigh 2.3-2.6 tonnes. The 600kg battery pack in the Mercedes EQC would on the AQEG/DEFRA model potentially increase nanoparticle emissions from tyres by 48-108%, compared to a conventional vehicle weighing 600kg less.

The same argument can be extended to internal combustion engine vehicles. A heavier vehicle increases tyre wear, whereas lightweighting mitigates it. This has implications for the broader market trend towards SUVs, where often particularly large rim tyre sizes are adopted.

On this basis we think tyres are set to be scrutinised and regulated more, and perhaps also reinvented for electric cars to perform well in durability and noise. There will be opportunities and threats that arise from these changes.

We anticipate the need to place a value on low emission tyres, so that they are desired and consumers are willing to pay for them, in other words using a tax policy that internalises the externality to the benefit both of society and the environment.

1 Costing the Earth: Tread Lightly. BBC Radio 4, March 13th, 2019.

2 Grigoratos & Martini, 2014.

3 Since 2010 the EU has required the discontinuation of the use of extender oils which contain more than 1 mg kg−1 Benzo(a)pyrene, or more than 10 mg kg−1 of the sum of all listed polycyclic aromatic hydrocarbons in the manufacture procedure due to increased health concerns related to PAHs (European Commission, 2005).

4 Microplastics are considered to be all plastic particles in the range of 0.1–5,000 µm. A secondary source is when a larger plastic object breaks down once already in a marine environment. The figure of 28.3% was originally cited in Julien Boucher, Damien Friot, Primary Microplastics in the Oceans: a Global Evaluation of Sources, International Union for Conservation of Nature and Natural Resources, 2017, p21.

5 Newby, David: ‘Air Pollution and Cardiovascular Disease - A Mills and Boon Classic’ (2019).