Independent analysis of the materials and compounds inside modern tyres

Tyres are complex chemical products

Beneath the tread pattern sits a mixture of natural rubber, synthetic polymers, fillers, plasticisers, stabilisers and antioxidants. Each manufacturer uses its own formulation and even small differences in chemistry can change how a tyre wears, how many particles it releases and how those particles behave in the environment.

Understanding tyre chemistry is essential for improving performance, durability and environmental impact. Our BTAS chemical analysis provides one of the most detailed and comparable datasets available.

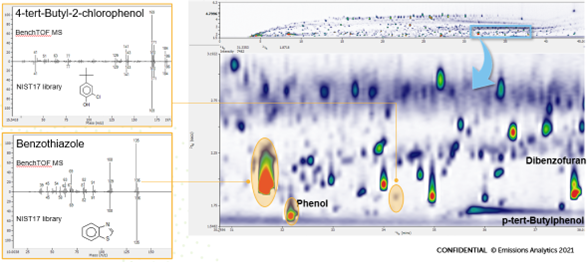

Tyres are a complex mix of components and compounds. To be able to separate and identify all the organic compounds, Emissions Analytics utilises two-dimensional gas chromatography coupled with time-of-flight mass spectrometry to yield a unique and detailed chemical fingerprint for each tyre using a specialised and highly-optimised form of analytical pyrolysis.

What we analyse

Using laboratory techniques and harmonised sampling, we profile the chemical composition of tyres across brands, sizes and categories.

Screening for targeted compounds, for example 6PPD

Testing and evaluation of source component and additives in tyre manufacturing

Full chemical fingerprint of original tyre and tyre wear material

Competitor monitoring and benchmarking

R&D testing of new formulations

Performance and stress testing

Failure analysis

Environmental degradation and leaching testing

Human health and environmental hazard estimation

Read more about our laboratory capabilities.

We measure:

Filler materials, including carbon black and silica

Polymer types and blends

Additives such as antioxidants and plasticisers

Key marker compounds of regulatory interest

Compounds linked to degradation pathways, including 6PPD and 6PPD-quinone

This builds a clear fingerprint of what each tyre is made from and how that chemistry may influence wear behaviour.

Why composition matters

Tyre chemistry affects:

Wear rate and longevity

Particle size and structure

Environmental mobility in air and water

Toxicity potential, depending on the compounds released

Performance characteristics, from grip to rolling resistance

Better understanding of these materials helps manufacturers innovate and gives policymakers evidence for future standards.

How we test

Emissions Analytics utilises two-dimensional gas chromatography coupled with time-of-flight mass spectrometry to yield a unique and detailed chemical fingerprint for each tyre using a specialised and highly optimised form of analytical pyrolysis.

Our laboratory process includes:

Careful sampling of tyre material from controlled locations

Chemical extraction and identification using established analytical techniques

Cross-comparison with BTAS wear and particle data

Consistent classification to ensure results can be compared across tyre models and years

The result is a scientifically robust, independent dataset trusted across industry and academia.

Explore BTAS in more detail

Upcoming conferences

Interested in chemical data or full BTAS access?

Speak with our tyre team to explore subscription options or tailored analysis.